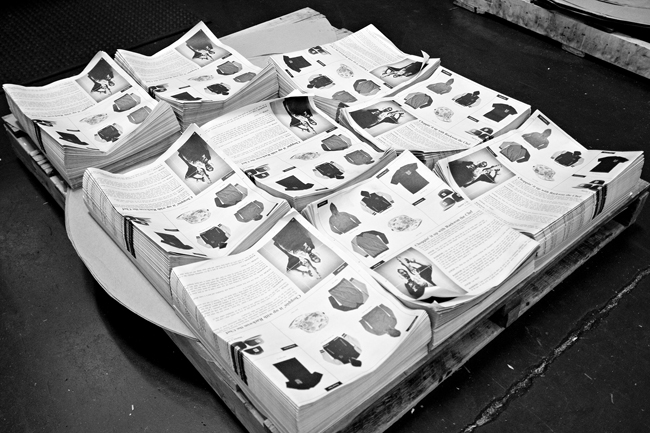

The other week the 3rd volume of the Akomplice Times went to press and I had a chance to stop by and document the entire process. This time around we decided to print the Akomplice Times on authentic newspaper at a printing press down in LA. These printing press machines were massive, with multiple levels to them and a crew of 5 guys to run just one press. Each press is capable of printing up to 5 sheets of paper, which are giant rolls, printed on both the front and back at the same time (that’s a 20 page newspaper). When running at full speed these presses can turn out 37,000+ copies per hour all printed, folded and stacked by the press. There is a ton of work that goes into prepping the press to get it up and running at full speed. Metal plates containing the design that will be printed on each side of the paper are hung at the top level of the machine. Once the plates are in place the crew begins running the press and papers start to come out, blank at first but slowly the design starts to appear as the papers come flying out of the press. The crew runs around checking the papers as they come out and making the necessary changes to the settings of the machine until the have the perfect print. All of the paper, until they achieve that perfect print, are tossed into the recycling bin that later go to the paper shredder and are recycled into paper they can use again. Once they approve the final print they run the press at full speed until the job is complete. These press crews work hard and are very good at what they do, they are like car mechanics, if something is printing wrong or running wrong with the machine they have boxes of tools and are trying to diagnose the problem and fix the press on the spot. After experiencing the printing press process, I have a new appreciation of the newspaper as a media type.

Check out more of the photos of the printing process after the jump.

-Blake P.